Why Don't We Have More Commercial Airplane Companies?

A deep dive into what's hard about building an aircraft company in the US today.

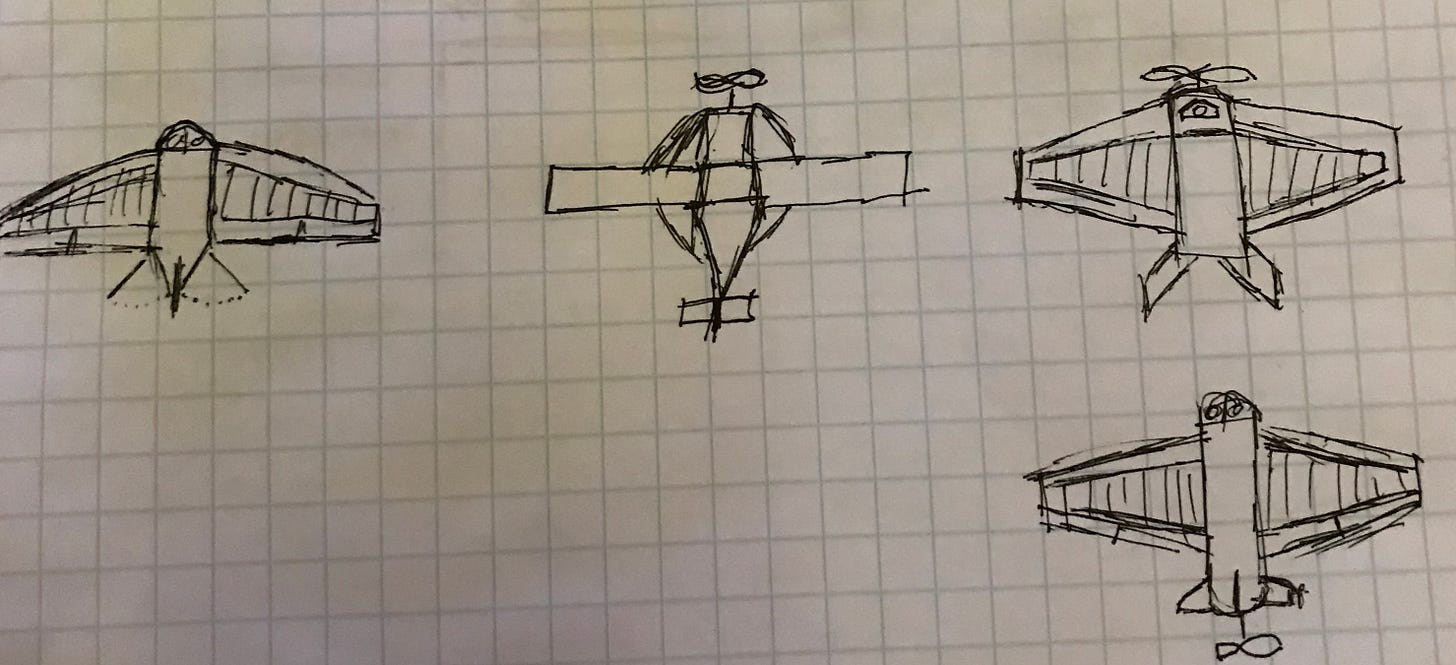

Almost nine years ago, a friend was starting a company to build an aircraft company to rival the likes of Airbus and Boeing. I was working on rockets at the time, and although I didn’t know too much about the aircraft industry, I know that the engineering practices were quite similar, so I joined as a co-founder.

Joining the company started my personal deep dive into figuring out exactly how hard it was to build new airplane and why no one seems to be doing it in the U.S.A.

Do We Need New Airplane Companies?

Of course this whole piece of writing would be pointless if we don’t actually need new airplanes. So do we?

Objectively, there is a huge backlog of commercial aircraft on order that seems to be growing at an almost exponential rate. In Nov. 2024, Airbus reported an order backlog of a 8,769 jets and Boeing reported a backlog of 6,268 jets. For Airbus that is over 10 years of shipments at their current rate. For Boeing, that is closer to 12 years. To make things even worse, in both companies, for every aircraft delivered they received at least two new orders. 1

Ouch. This implies that there is a huge demand for new aircraft that the incumbents simply can’t satisfy.

Subjectively, think back to the last time you took a commercial flight. Did it feel nice? Did the airplane fill you with a sense of wonder for being in the marvelous futuristic year of 2025? I’m guessing probably not. If you are like me, you probably felt most like you were riding in some sort of bad movie set from a movie in the year 1978. Everything is sorta dirty ( in an artistically quaint, but still off-putting way ), you noticed several screws or pieces of trim missing off of things, and you were filled with the general sense that the last city bus rated higher on the niceness per dollar scale than this flight.

Why Don’t Airbus / Boeing Just Build a Better Airplane?

Well I am sure that they wish they could, but there are two factors that keep them from doing so.

The Innovator’s Dilemma - If you aren’t familiar with the concept, there are many books about it, but to paraphrase, it’s the idea that big, successful companies almost always fail after some time because they become overwhelmed with maintaining the status quo while new entrants steal all their customers with better offerings. Based on the current research this phenomenon is still very much alive and well. 2 There are lots of reasons why this occurs, that have been studied often and although I won’t discuss it here, I find it to be a fascinating topic.

The backlog of current generation jets prevents them from doing so. Clearly, the incumbent companies can’t keep up with their current backlog, so how could we reasonably expect them to develop new aircraft? Strangely, executives may actually be prevented to seriously fund new aircraft development in the face of the huge backlog due to a corporate governing concept called “fiduciary duty” and various interpretations of that. Many executives take this concept to mean that they have a responsibility to make as much money for their shareholders as possible (whether this is the correct legal interpretation or not is the subject of countless debates, but many executives definitely operate as if it is the case). If you are an executive with this mental operating framework, then likely you would not choose to develop new products when you have ever increasing demand for your existing ones.

So It’s Up to Startups to Disrupt, Why Don’t They Build It?

The short answer: it’s incredibly expensive to do so.

The Boeing 747 cost around a billion dollars to build in the 1960s. 3 That’s around $10 Billion today.

The image below, which comes from the excellent article “A Cycle of Misery: The Business of Building Commercial Aircraft“ lists other recent costs. 4

So we can estimate the cost of building a commercial aircraft to be somewhere around $10 → $30 Billion by the incumbent companies. Now, when I put on my optimistic startup founder hat, of course I would make the argument that a new, disruptive company could do it for less. For the sake of argument let’s assume that’s true. Let’s say you are the absolute best and you can do it for 5 times less money, which seems a bit optimistic, we are still looking at $2 → $6 Billion for a new aircraft.

Let’s look at how VC’s distributed their money in the U.S., in 2024. According to my sources (which are perhaps somewhat dubious as lots of these numbers aren’t public), there was around $190.4 billion that went out in 2024. 5

Great, that should be enough right? Wrong, because only $12 Billion of that went to transportation, while more lucrative industries like “Enterprise Software” gobbled up the remainder.

So to be confident you could build an airplane in the U.S.A. this year, you would need to bank on raising something like half of the available funding for transportation startups, which seems challenging to do.

It’s even more challenging because most professional investors I know wouldn’t touch an aviation pitch deck with a 10 meter helicopter rotor. Almost every big firm made some sort of bad investment during the EVOTL funding hype bubble of the last 10 years or so and although the problems with that industry are largely unrelated to commercial jet aircraft, investors still have bad taste in their mouth. 6

Dual Use?

One other commonly discussed idea in the industry is to tap into the larger pool of federal defense funding (via grants or R&D contracts) to fund the development of a new aircraft that is considered “Dual Use” meaning that it has both military and commercial applications. The idea is common and there are even investment organizations run by the military specifically to fund ideas like this with names like the “Army Venture Capital Initiative”. 7 This is good in theory and has worked well in the past for other projects like the Jeep.

The concept works well for things like cars or certain types of thermal cameras, but it’s never really worked for commercial aircraft. The problem with military things is that they have secret military features and theoretically afford some military advantage to the company that produces and operates them (example: China’s cheap global drone dominance). So in order to counteract this, governments pass laws to prevent the technology and knowledge about how the technology works from leaking outside of the home country. In the United States, we have the International Traffic in Arms Regulations (ITAR). 8 This works ok for radios and thermal cameras which can largely be checked at borders and the information about how they work and how to fix them can be kept a general secret.

Much to the dismay of the dual-use proponents, commercial aircraft must fly and more importantly be serviced and repaired globally. This means that service manuals and training that deeply explain exactly how everything works must be distributed globally to airports and airlines all over the world. This makes military leaders everywhere squirm and explains why most military aircraft of the world are developed by obtuse and secretive corporations that seem intent on continuously combing themselves to form longer and longer streams of random names tacked together (I’m personally waiting for the singularity of Lockheed-Northrop-Grumman-Martin-Harris).

So What to Do?

Well, I’ll be honest the situation is bleak and I’m not 100% sure what to do or you can bet I would be out there doing it. I haven’t even gotten into all the interestingly hard issues about why building an airplane is so difficult.

It seems like there are two main strategies for the U.S.A. to consider:

Hope that the U.S. Federal Government will step in and provide strategic large scale funding without relying on dual-use mechanisms.

Hope that the private industry VC’s have a change of heart and collectively start funding the next wave of companies.

Given the current state of U.S. politics and the lean towards less government funding into private industry, it would seem unlikely that option 1 will occur in the U.S. anytime soon. Maybe I’m wrong though and if you work in government and see a path forward, please let me know how I can help.

That leaves option 2, which I think is almost equally challenging for reasons I stated above, but at least you don’t have government leaders actively opposing the direction.

So if you are a professional investor, maybe give an aircraft company a second look if they ask for funding. Your comfy business class seat depends on it.

If aren’t a professional investor, consider writing your local venture capitalist an email or something. They are smart, information brokers and do listen to the popular zeitgeist, so maybe we can collectively create the public ground swell they need.

Happy New Year and let me know if you would like to hear more about what’s hard in airplane building in future articles.

Sources

https://flightplan.forecastinternational.com/2024/12/30/airbus-and-boeing-report-november-2024-commercial-aircraft-orders-and-deliveries/

https://sloanreview.mit.edu/article/how-leaders-delude-themselves-about-disruption/

https://simpleflying.com/how-much-did-the-boeing-747-cost-to-build/

https://www.techloy.com/chart-us-venture-capital-surges-to-190-4-billion-in-2024-driven-by-ai-megarounds/#:~:text=U.S.%20VC%20funding%20hit%20%24190.4,%242M%2B%20closed%20in%202024.

https://airinsight.com/the-coming-evtol-collapse/

https://asc.army.mil/docs/pubs/alt/2003/6_NovDec/articles/28_Army_Venture_Capital_Initiative_200306.pdf

https://www.pmddtc.state.gov/ddtc_public/ddtc_public?id=ddtc_kb_article_page&sys_id=24d528fddbfc930044f9ff621f961987